To date, several approaches have been proposed to harvest energy from different energy sources, such as thermal, solar, RF, or mechanical sources [1], using thin films and MEMS technologies. With the advent of ultra-low power circuits, the energy needed for autonomous systems can be harvested by ever smaller structures and, eventually, nanostructures. Moreover, some properties of nanostructures can be controlled and improved compared to bulk [2, 3]. We discuss the state-of-the-art and prospects of mechanical energy harvesting using nanostructures, taking into account integration issues.

One of the main characteristics of nanowires is that their resonance frequencies reach the MHz range, leading to new applications for vibrational energy harvesting. At lower frequencies, nanowires can harvest energy from deformations. The most studied materials have been ZnO, and more recently GaN.

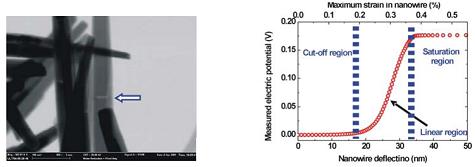

Prototypes of mechanical energy harvesters have been demonstrated based on ZnO nanowires, with a power density of ~11 mW/cm3 [4], which starts to be comparable to that of MEMS devices (~0.1-40mW/cm3 [5]). Gallium nitride offers better integration prospects with silicon. It is chemically stable and

both n- and p-type doping can be achieved. Moreover, it has been shown recently that the piezoelectric coefficients (d33) can be increased from 0.73 for bulk material to 3.36 C/N2 for nanowires [3]. This leads to higher generated power, for a given deformation. Recent results show how these properties can be

further improved (by an estimated factor of 9) in heterostructured GaN NWs including an AlN barrier

(Fig. 1) [6]. In the future, it is expected that autonomous systems will harvest energy from multiple sources for energy availability reasons. Towards this end, some devices harvesting solar and mechanical energy using nanostructures have been recently reported in the literature and will be discussed [7].

Fig. 1. (a) STEM image and (b) measured potential vs. deflection of a GaN/AlN/GaN hetero-NW [4].

1. K. A. Cook-Chennault, N. Thamby, and A. S. Sastry, Smart Mater. Struct. 17, 043001 (2008).

2. D. Li, Y. Wu, P. Kim, et al., Appl. Phys. Lett. 83, 2934 (2003).

3. M. Minary-Jolandan, R. A. Bernal, I. Kuljanishvili, et al., Nano. Lett. 12, 970 (2012).

4. X. Xu, A. Potie, R. Songmuang, et al., Nanotechnology 22, 105704 (2011)

5. G. Zhu, R. Yang, S. Wang, and Z. L. Wang, Nano Lett. 10, 3151 (2010).

6. P. D. Mitcheson, E. M. Yeatman, G. K. Rao, et al., Proc. IEEE 96, 1457 (2008).

7. C. Xu and Z. L. Wang, Adv. Mater. 23, 873 (2011).